Tactile switches are switches whose operation is perceptible by touch. LCSC Electronics supplier Korean Hroparts Elec shares knowledge about tactile switches. What are the circuit requirements of tactile switches? And what are the particularities and structural requirements of ultra-small tactile switches?

Tactile Switches Circuit Design Requirements

It should pay attention to the temperature when considering the working status of the tact switch circuit. Temperature plays a vital role in the effect of switching. At reasonable and appropriate temperatures, we can make our equipment work well. The maximum temperature of the equipment must not exceed 40 degrees. Once it exceeds 40 degrees, it will cause damage and degradation. The minimum temperature must not be lower than 5 degrees. Once temperatures are below 5 degrees, it can cause significant damage to power supplies and electrical equipment, leading to major disruptions.

The touch switch circuit can serve at high altitudes. It has high adaptability. The strong adaptability has attracted the attention of many people, and it has also given it unlimited attention and applications. However, it is best not to install the tact switch circuit for more than two kilometers. Beyond two kilometers, there will be a negative impact. In outdoor environments, tact switches face challenges such as climate change, temperature fluctuations, and dust intrusion. That will cause pollution to circuit equipment. We should fully consider the factors in the design.

Some small tact switches have very high application value. These lightweight, high-tech, high-value-added small products will receive more attention and applications in future life.

Ultra-Small Tactile Switches Particularities and Structural Requirements

First, let’s look at the external structure. Ultra-small tact switches are to keep the product size as small as possible. Therefore, how to ensure its product function in a limited space has become an issue. Everyone knows that the smaller the product, the higher the precision. The materials of the base and contact reed are also vital. Because they directly affect the insulation and conduction performance of the switch. In the base part, LCP or PA materials serve for injection molding.

Additionally, most of the shrapnel of ultra-small tact switches use imported stainless steel shrapnel, and its processing technology is strict. After being treated with silver electroplating, it can achieve good contact performance and anti-oxidation effects.

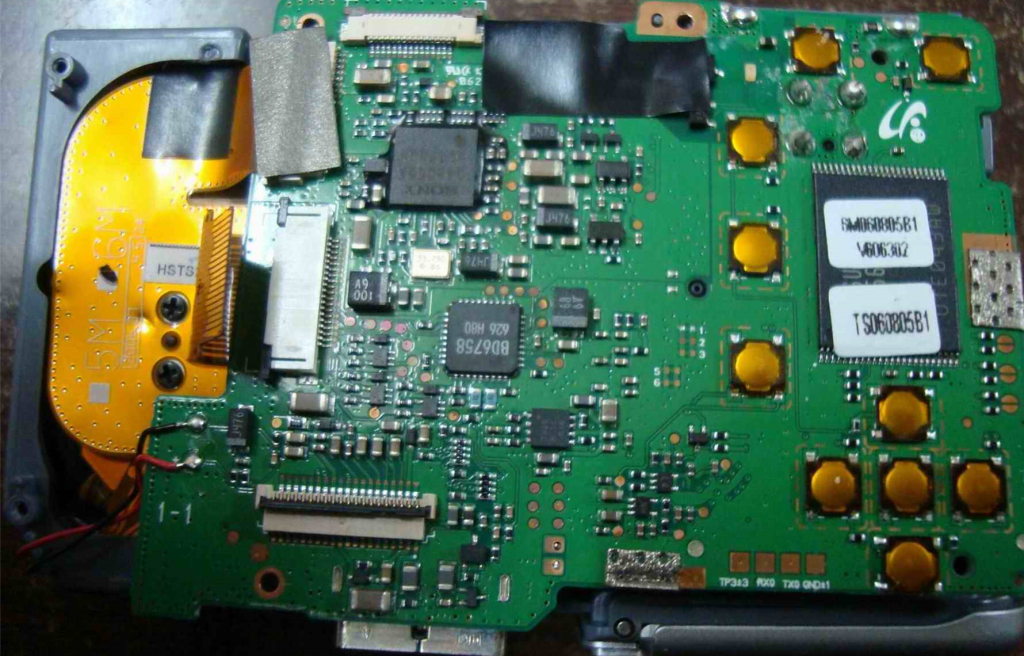

Then, let’s look at the surface parts again. The yellow or transparent film protects the switch very well. Switches generally need to consider the feel, so the thickness of the diaphragm is also very particular. If it serves in special fields, there will also be requirements for the product’s temperature range and waterproofing properties.

Generally speaking, as an exploration of the lightweight and miniaturization of ultra-small tact switches, Korean Hroparts Elec has developed into a mature solution provider, and its products find applications in mobile phones, tablets, wearable devices, and other products.

Korean Hroparts Elec is strict in controlling the production quality of its products. While focusing on quantity, it ensures good quality. It provides excellent quality, good service, and highly competitive prices to win customers’ trust. When buying tactile switches, choose the Korean Hroparts Elec brand on LCSC.

This article is translated from supplier Korean Hroparts Elec to convey more information. It does not mean LCSC Electronics agrees with its views and is responsible for its authenticity. It is for learning and communication purposes.