Hello everyone, this week LCSC supplier BORN will introduce the basics of the gas discharge tube (GDT). The topics covered will include the working principle of the GDT, its characteristics, a description of its parameters, and considerations for selection.

1. Working Principle of Gas Discharge Tube

A gas discharge tube (GDT ) is a ceramic gas discharge tube. GDT is a device with one or more discharge gaps encapsulated in a ceramic tube filled with inert gas. The electrical performance of GDT depends on factors such as gas type, gas pressure, internal electrode structure, and manufacturing process. GDT can withstand surge current impacts of up to tens or even hundreds of kiloamperes, has extremely low junction capacitance, and is used to protect electronic equipment and individuals from the hazards of transient high voltage. Figure 1 is a typical GDT volt-ampere characteristic curve.

2. Features of Gas Discharge Tube

- Lowcapacitance, most series products have a capacitance of no more than 2pF, with extra high current products ranging from tens to several tens of picofarads.

- DC breakdown voltage range is 75V~6000V, pulse breakdown voltage range is 600V~7800V.

- High insulation impedance, generally above 1GΩ, not easy to aging, high reliability.

- Diverse packaging options, including surface-mounted and through-hole devices, two-terminal and three-terminal devices, round and square electrodes, meeting different application needs.

3. Parameter Description of Gas Discharge Tube

DC Spark-over Voltage (DC Breakdown Voltage)

We measure the DC spark-over voltage of a GDT by applying a slowly increasing DC voltage and observing the voltage level at which the GDT initiates a spark. This is also referred to as the DC breakdown voltage. We measure the DC breakdown voltage of a GDT at a rate of rise not exceeding 100V/s. Before taking the measurement, we place the GDT in the dark for at least 24 hours without applying any voltage. Utilizing the test circuit depicted in Figure 6, we apply a voltage rise rate of 100 (1±10%)V/s. For each polarity, we record two measurements between the A and C poles of each GDT, ensuring that there is a minimum interval of 1 second between the two readings. When testing a three-pole GDT, we measure each pair of terminals separately, leaving the remaining terminal unconnected. We ensure that all recorded measurements adhere to the product specifications.

DC Spark-over Voltage: DC breakdown voltage, the measured voltage should be applied at a rise rate of no more than 100V/s.

Maximum Impulse Spark-over Voltage: Pulse breakdown voltage, the voltage is applied at a voltage rise rate of 1000V/μs.

Nominal Impulse Discharge Current: Nominal discharge current, generally 8/20μs pulse current is applied, 10 times, 1 min intervals.

Alternating Discharge Current: Power frequency withstand current, applied 50Hz, 1s.

Impulse Life: Impulse current life, generally 10/1000μs pulse current is applied several times.

Minimum Insulation Resistance: Minimum insulation resistance, measured by applying a certain DC voltage.

Maximum Capacitance: Maximum capacitance of GDT.

Maximum Impulse Spark–over Voltage (Impulse Breakdown Voltage)

We define the maximum impulse spark over voltage, also known as the impulse breakdown voltage, as the highest voltage observed between the two terminals of a GDT before the discharge current flows through it when subjected to an impulse voltage with a specified rise rate and polarity. Typically, we measure this voltage value at a rise rate of 1000 (1±10%) V/μs. In the GDT selection precautions section, we discuss the distinction between this parameter and the DC breakdown voltage.

To measure the impulse breakdown voltage of a GDT, we first place it in the dark for at least 15 minutes without applying any voltage. Following this, we use the test circuit illustrated in Figure 7, applying a voltage rise rate of 1000 (1±10%) V/μs. For each polarity, we record two measurements between the A and C poles of each GDT, ensuring there is a minimum interval of 1 second between the readings. When testing a three-pole GDT, we measure each pair of terminals individually, while the third terminal remains unconnected or floating. We ensure that all recorded measurements conform to the product specifications.

Nominal Impulse Discharge Current

We define the nominal impulse discharge current as the peak value of the impulse current with a specified waveform, which is typically an 8/20μs pulse current waveform and represents the rated value of the GDT. This parameter is crucial for measuring the GDT’s tolerance to impulse currents. When conducting the measurement, we use an unused GDT test piece and apply an impulse current value as specified in the GDT’s technical specification. For a two-pole GDT, we utilize a test circuit that generates an 8/20μs waveform, as depicted in Figure 8.

The impulse current measurement should have a sufficiently long time interval so as not to overheat the GDT. We verify the specified nominal impulse discharge current and its timing by employing a short circuit in place of the GDT. For a three-pole GDT, we ensure that each electrode discharges to the common electrode simultaneously, as illustrated in Figure 8, adhering to the specified values for each nominal impulse discharge current as outlined in the specification. After the completion of the specified number of current applications, we allow the GDT to cool down to the ambient temperature. Within one hour following the application of the last current, we measure the DC breakdown voltage, pulse breakdown voltage, and insulation impedance of the GDT to ensure they fall within the specified range.

Impulse Life

This parameter measures the ability of the gas discharge tube (GDT) to withstand multiple impulse currents and reflects the stability and reliability of GDT to a certain extent. When testing the impulse current life of GDT, it uses an unused GDT and applies the impulse current according to the value specified in the GDT specification. It uses one polarity for half of the specified test times and the opposite polarity for the other half or uses one polarity for half of the GDTs and the opposite polarity for the other half. The repetition frequency of the impulse should be appropriate to prevent heat accumulation inside the GDT.

The voltage of the power supply should exceed the GDT’s maximum impulse spark-over voltage by at least 50%. The specified impulse current and waveform should be measured using a short circuit in place of the GDT. For a three-pole GDT, each electrode should discharge to the common electrode at the same time, and the specified value of each impulse current is as specified in the GDT specification. For example, Figure 9 is a test circuit that generates a peak current of 100A and a waveform of 10/1000μs. We conduct tests on the GDT after each impulse current test, and with the consent of both the user and the manufacturer, we may reduce the frequency of these tests to ensure the GDT complies with the specifications outlined in the manual.

4. Selection Considerations for Gas Discharge Tube

DC Spark-over Voltage and Impulse Spark-over Voltage

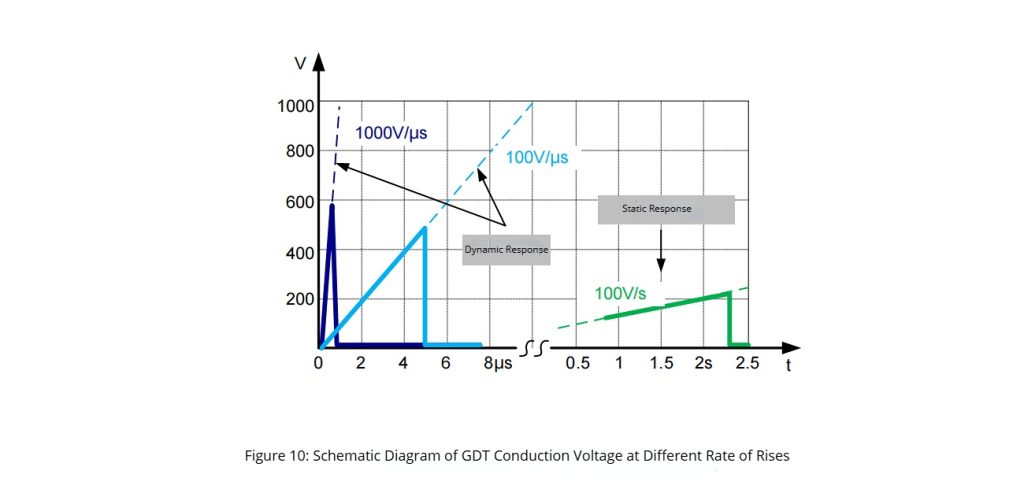

When selecting a GDT, we must actively consider the distinction between DC-Spark-over Voltage and Impulse Spark-over Voltage. We choose the DC-Spark-over Voltage with reference to the operating voltage of the circuit, ensuring it is higher than the maximum operating voltage of the circuit to be protected; otherwise, it will interfere with the circuit’s normal functioning. We also take into account the surge test level when determining the Impulse Spark-over Voltage. Typically, the surge test waveform’s rise time is a microsecond-level pulse, such as an 8/20μs current pulse and a 10/700μs voltage pulse, which corresponds to the same order of magnitude as the 1000V/μs voltage rise rate used for measuring the GDT’s Impulse Spark-over Voltage.

For instance, if we use a 10/700μs waveform to test at 4000V, we ensure that the GDT’s Impulse Spark-over Voltage is set below 4000V to allow the GDT to conduct during the test. Figure 10, which we actively refer to, is a schematic diagram illustrating the conduction state of the GDT at various voltage rise rates. It clearly shows that an increased voltage rise rate results in a higher breakdown voltage for the GDT.

The Continuous Current Issue of Gas Discharge Tube

As depicted in Figure 1, we utilize a gas discharge tube (GDT) as a switch-type overvoltage protection device. Once we activate it, the GDT maintains a low voltage, precluding its standalone use for high-power line protection. We refer to the GDT’s continuous current as a scenario where, post-activation, if the working voltage of the protected circuit exceeds the GDT’s on-state voltage, the GDT remains active. Prolonged passage of a large current at the ampere level through the line can result in damage to both the GDT and the circuit.

Package Form

Choose a suitable package form according to the circuit design layout. The size of the gas discharge tube (GDT) device package can reflect the protection level of the device to a certain extent. Generally, the larger the package, the stronger the ability of the device to withstand impact current and the higher the protection level, and vice versa.

Bornsemi (Shenzhen) Co., Ltd. (BORN) is a semiconductor company with independent research and development, design, production and sales as its main body. It is a high-tech enterprise specializing in wafer design, development, production and sales of protection devices and power devices.

LCSC is a global distributor offering a broad selection of electronic components, with more than 4 million registered customers worldwide. LCSC Electronic, with its in-stock inventory, ensures fast delivery as it owns 130,000㎡ of intelligent warehouses. View and select BORN‘s products on LCSC.