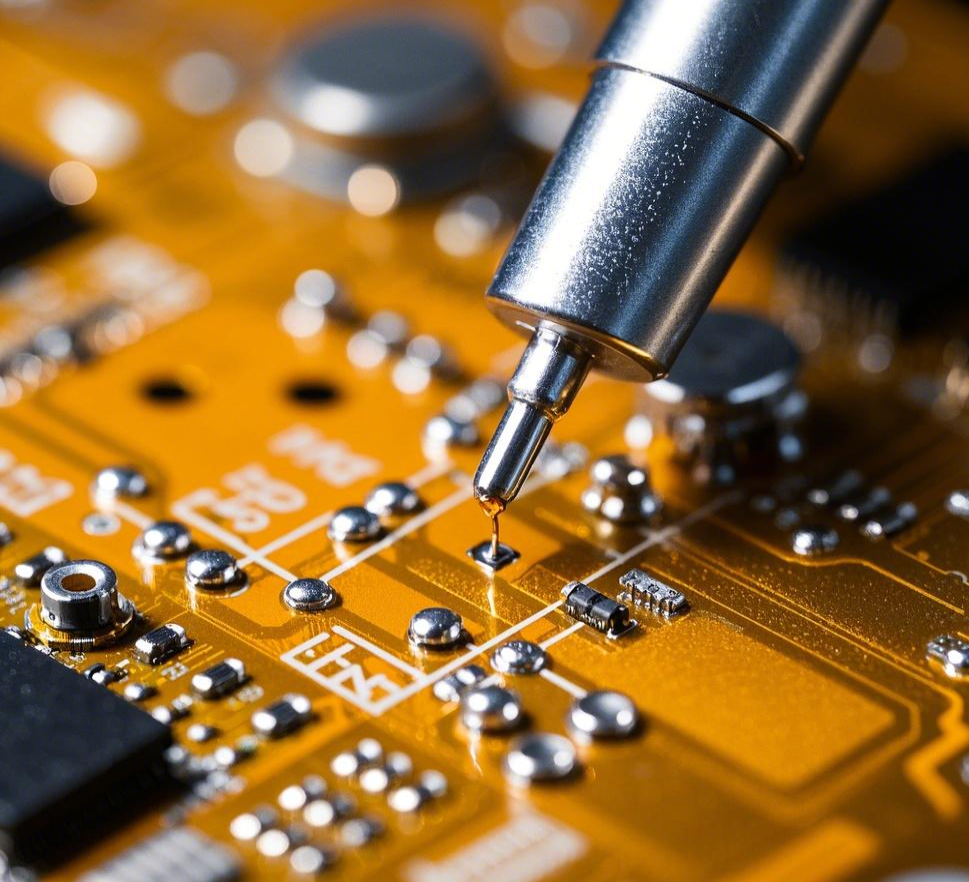

Solder joints, though often overlooked, are the unsung heroes of modern electronics. Like the joints in a human skeleton or the veins in a living organism, these tiny metallic connections serve as the “lifeline” for electronic devices. They bridge components to circuit boards, enabling electrical signals to flow and ensuring structural integrity. But what happens when these microscopic links fail? Let’s explore how solder joints shape the reliability, performance, and lifespan of the gadgets we rely on daily.

Anatomy of a Solder Joint: More Than Just Metal

A solder joint is a fusion of metal alloys (traditionally tin-lead, now mostly lead-free alternatives like Sn-Ag-Cu) that bonds electronic components to printed circuit boards (PCBs). Its structure includes:

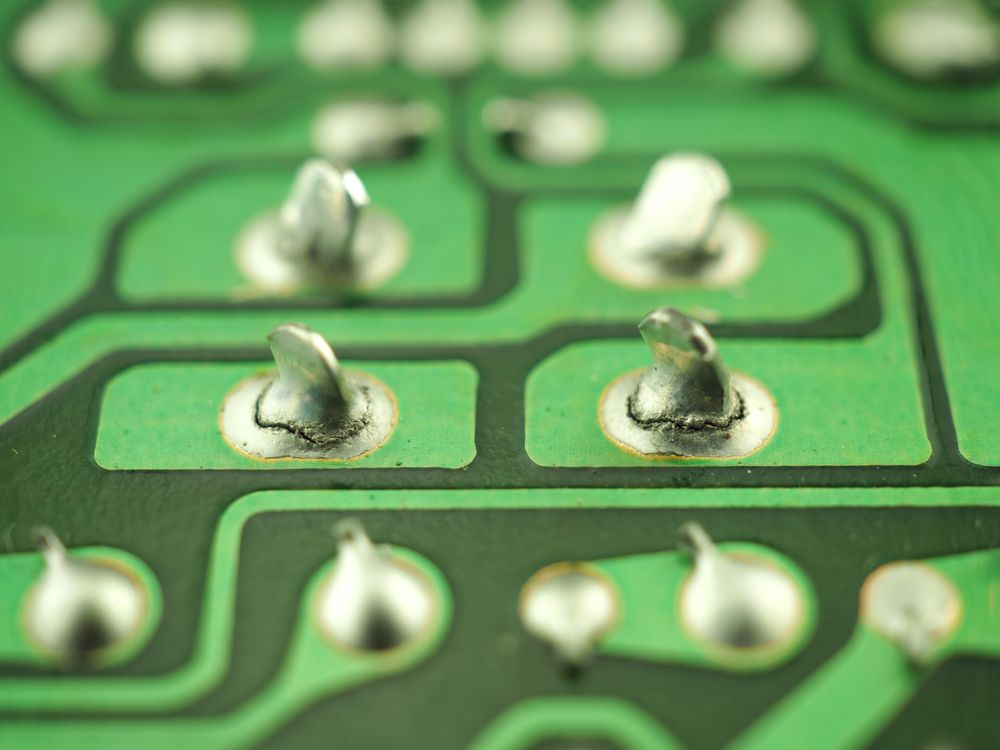

Metallurgical Bonds: Formed when molten solder wets and adheres to copper pads and component leads.

Intermetallic Compounds (IMCs): Thin layers (e.g., Cu₆Sn₅) at the interface, critical for conductivity but prone to brittleness over time.

Microscopic Textures: Grain boundaries and voids that influence mechanical strength.

Think of solder joints as the “cartilage” in a device’s skeleton—flexible enough to absorb stress but vulnerable to wear.

The “Lifeline” Role: Why Solder Joints Matter

Electrical Continuity

- Signal Highways: Solder joints transmit power and data between components. A single faulty joint can disrupt an entire circuit, akin to a blocked artery causing organ failure.

- Resistance Risks: Poorly formed joints increase electrical resistance, generating heat and accelerating device aging.

Mechanical Stability

- Vibration Resistance: Devices like smartphones and automotive electronics endure constant shaking. Strong solder joints act as shock absorbers.

- Thermal Stress Management: Repeated heating/cooling cycles (e.g., in CPUs) cause expansion and contraction. Robust joints prevent cracks.

Silent Killers: How Solder Joints Fail

- Voids and Cracks: Air pockets or fractures (visible under X-ray) weaken joints, akin to “clogged veins” disrupting blood flow.

- Intermetallic Growth: Over time, IMC layers thicken, turning joints brittle—a common issue in high-temperature environments like server farms.

- Whiskers: Tiny metallic filaments (often tin) that grow from joints, risking short circuits.

Fighting Failure: Innovations in Solder Joint Technology

Material Science Breakthroughs

- Nanoparticle-Reinforced Solders: Adding nanoparticles (e.g., TiO₂) improves strength and thermal stability.

- Self-Healing Solders: Experimental alloys that “repair” microcracks autonomously, inspired by biological systems.

Smart Manufacturing

- AI-Powered Inspection: Machine learning algorithms analyze X-ray or AOI (Automated Optical Inspection) data to detect defects invisible to the human eye.

- Precision Soldering Robots: Laser-assisted systems create ultra-reliable joints for 5G antennas and EV battery modules.

The Future: Solder Joints in Next-Gen Electronics

- Flexible Electronics: Stretchable solder materials for foldable phones and wearable devices.

- Quantum Computing: Ultra-low-resistance joints to minimize signal loss in quantum chips.

- Sustainability: Bio-based fluxes and recyclable alloys to reduce environmental impact.

From smartphones to spacecraft, solder joints are the fragile yet vital links that keep our digital world alive. As devices shrink and demands grow, advancing solder joint technology isn’t just about engineering—it’s about safeguarding the invisible “lifeblood” of modern innovation. By understanding their microscopic world, we can build electronics that are faster, smaller, and far more resilient.

Some images are sourced online. Please contact us for removal if any copyright concerns arise.

Custom Cables: Save 50%+ Avg Cost By JST, Molex, TE Alternatives | Processing Fee Down to $1 Per Piece | No Minimum Order Quantity (MOQ) Required

PCB & PCBA: New Customer Get Coupons Up to $125 | 1 – 32 Layers From $2 /5pcs | PCB Assembly From $8 /5pcs

Front Panels: High-quality Front Panel Acrylic/PET | Front Panel Order Up to 30% Off | Membrane Switch Available Soon