Material

non-woven cotton paper adhesive with a thickness of about 0.15mm

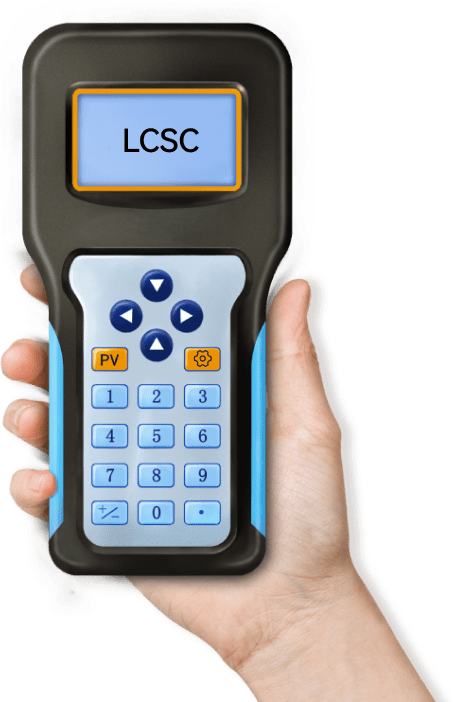

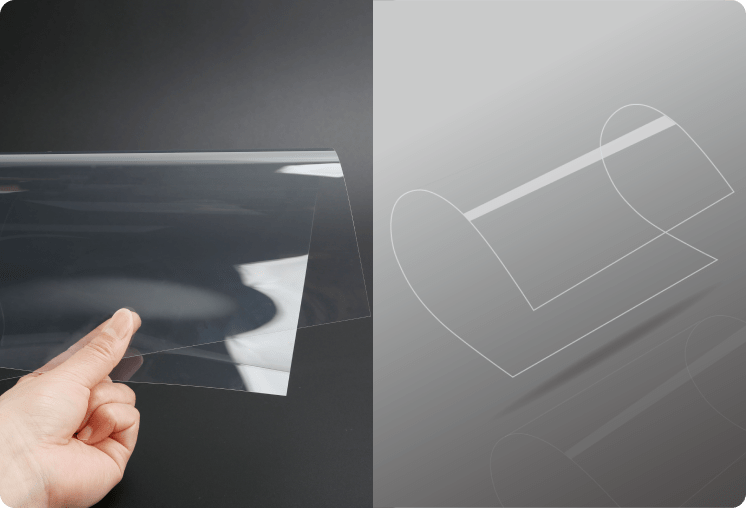

Acrylic Front Panel

"Acrylic" (PMMA) is a polyacrylate material, akin to treated plexiglass. It offers transparency, stability, weather resistance, aesthetics and easy coloring/processing. With 92% light transmittance and half the weight of glass, it's shatter-resistant (12-18x glass), strong (10x+ glass), weatherproof, electrical insulation, and chemically stable. A thickness of 0.8mm acrylic front panel is flexible and can be bent by hand.

Please Order Now

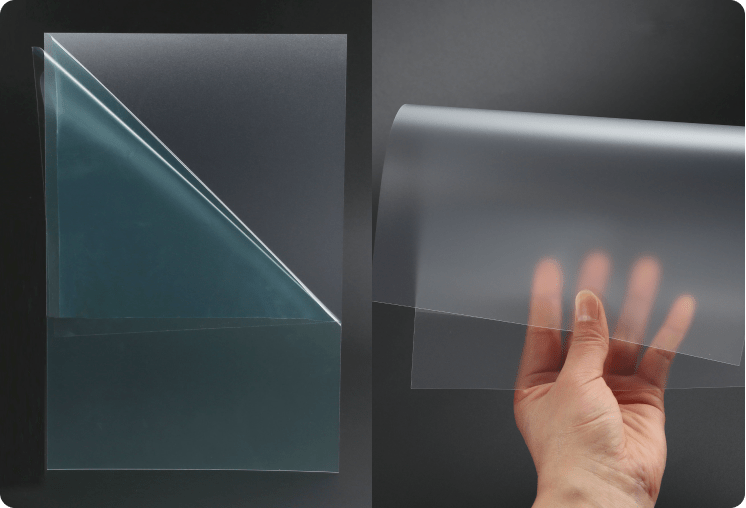

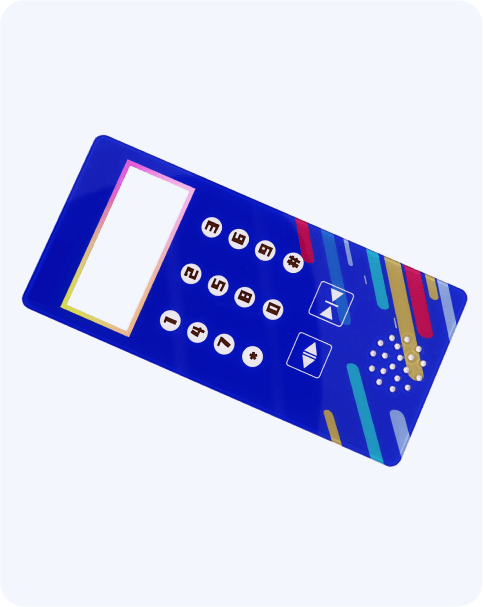

PET Front Panel

PET excels in drug, acid & alkali resistance, insulation, heat & wear resistance, strong toughness, and dimensional stability. Ideal for high-demand instruments and appliance front panels as it outperforms PC front panels in button longevity. As a premium substrate for film switches & circuits, PET front panels with light transmission, shading, water-proofing, and dust-proofing. Widely applied in appliances, communications, instrumentation, industrial control, etc.

Please Order Now

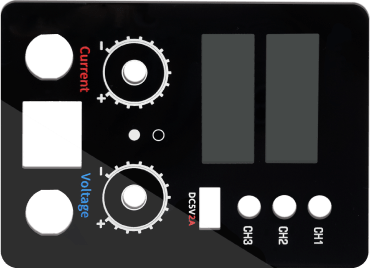

Transparent Acrylic Front Panel

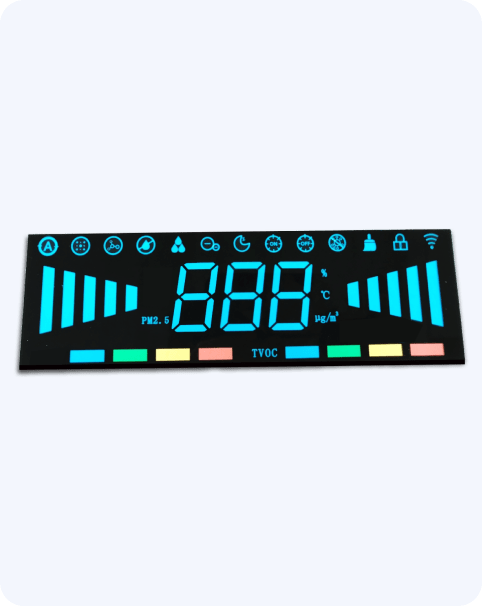

The transparent acrylic panel material turns colorful upon ink printing and can cater to diverse light transmission needs, ranging from fully transparent to semi-transparent to fully opaque. Now LCSC supports the transparent acrylic front panel thicknesses are 0.5mm, 0.8mm, 1mm, 1.5mm, 2mm, 2.5mm, 2.8mm, 4mm, and 6mm.

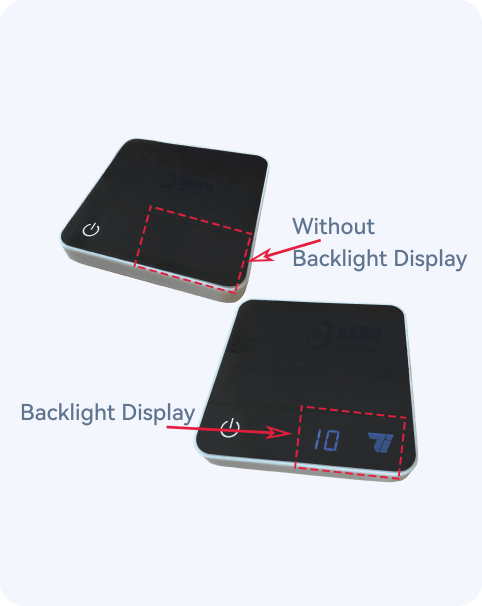

Black Semi-transparent Acrylic Front Panel

The raw material is naturally semi-transparent, with a light transmittance of about 15%. Without light, it appears black, yet when illuminated, it allows light to pass through.

Frosted Acrylic

Glossy PET

Frosted PET

1. Default adhesive applies to the back. For the front application, specify during the order or contact frontpanel@lcsc.com.

2. Double-sided adhesive requires two pieces - one for the front and one for the back of the front panel.

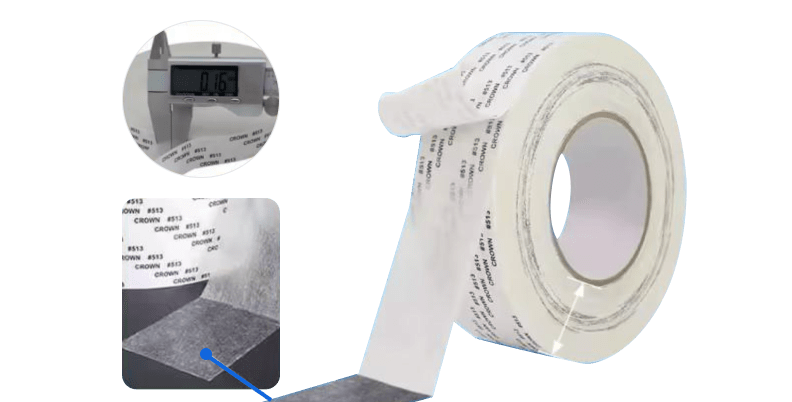

non-woven cotton paper adhesive with a thickness of about 0.15mm

white translucent

70℃(long-term)~150℃(short-term)

14N/10mm

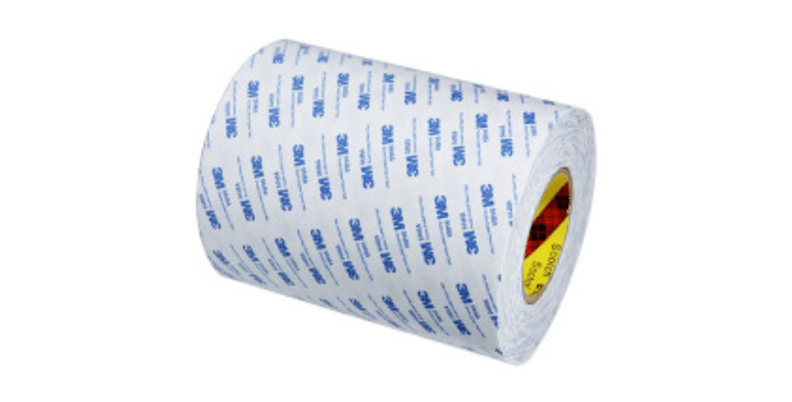

It's a universal double-sided adhesive, boasting durability, superior temperature resistance, and robust adhesion, ideal for conventional front panels. Note: Repeated pasting is discouraged for optimal longevity.

pure adhesive film without substrate with a thickness of about 0.13mm

transparent

149℃ (long term) ~ 204℃ (short term), (minimum temperature is-30℃)

8.5N/10mm

Anti-slip, waterproof, easy to process, temperature-resistant, and features strong adhesion for a secure bond. Release paper is waterproof kraft with polymer coating, resisting wrinkles in humidity and temperature variations. Note: Repeated pasting is not advised.

High-dialysis cotton paper substrate, with a thickness of 0.16mm

white translucent

80℃(long-term)~100℃(short-term)

11.5N/10mm

Excellent dimensional, thermal, chemical stability, and moisture resistance. Good anti-rebound & anti-warping properties. Applied for wood, metal, glass, paper, paintings, plastics, and textiles; ideal for nameplates, membrane switches, etc.

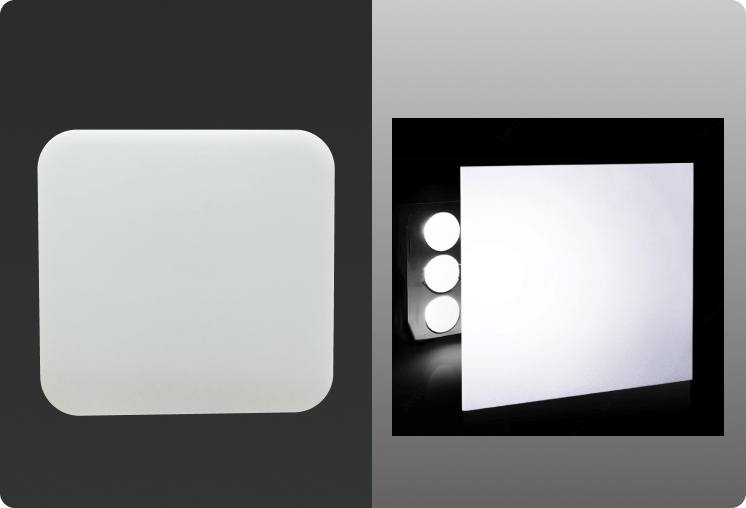

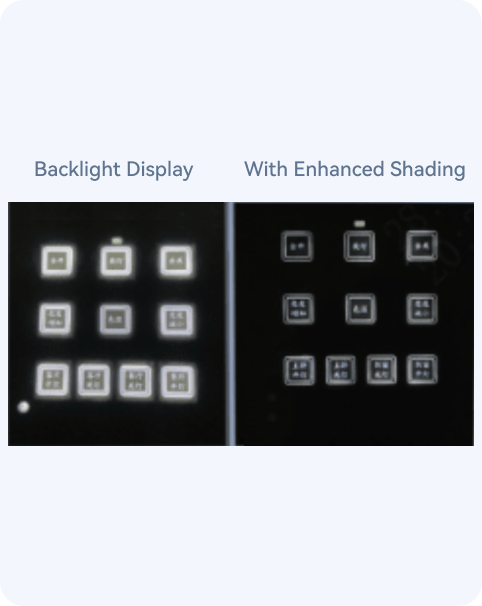

Compared to normal shading, the front panels add a light-shielding underlayer, which can prevent light sources to the surrounding areas.

Note: Neither normal shading nor enhanced shading will affect transparent and translucent windows.

LEDs or strong lights under the front panels may cause glare with normal shading. Applying a stronger shading layer significantly reduces glare.

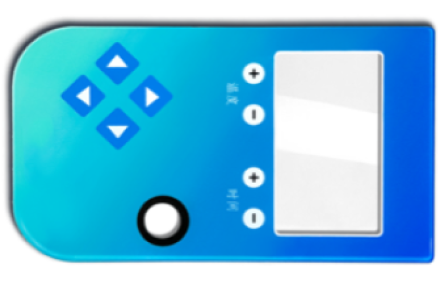

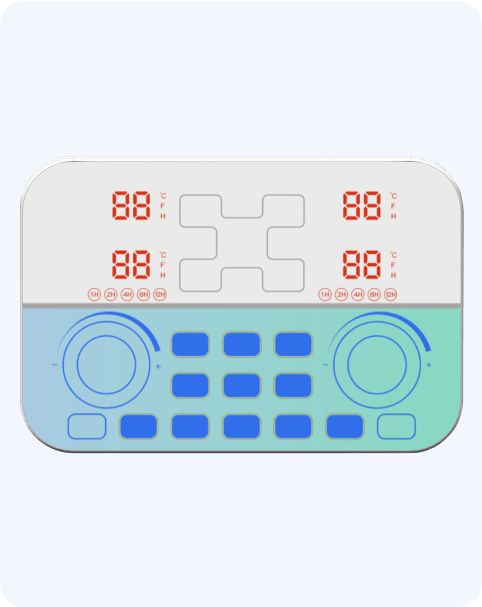

1.Bulged buttons on PET front panels are made by a hydraulic press to bulge the button area on the film layer.

2.Enhancing recognition speed, offering a stronger tactile feeling on front panels for users, and accurately indicating the range of the keys.

3.The basic shapes include spherical bulges, elliptical bulges, rounded rectangular bulges, etc.

4.The height range is within 0.3~0.6mm, typically at 0.45mm.

Black translucent acrylic front panel material blends with a screen in the dark but reveals under light. Adding a black underlayer to non-display areas can enhance a visual appeal.

LCSC supports translucent colors in the front panels. Customers must mark CMYK color & text ("red translucent") in drawings.

Note: Use "red translucent" instead of "red transparent" to avoid confusion.

A transparent window can make users see clearly what it is underneath the front panel.

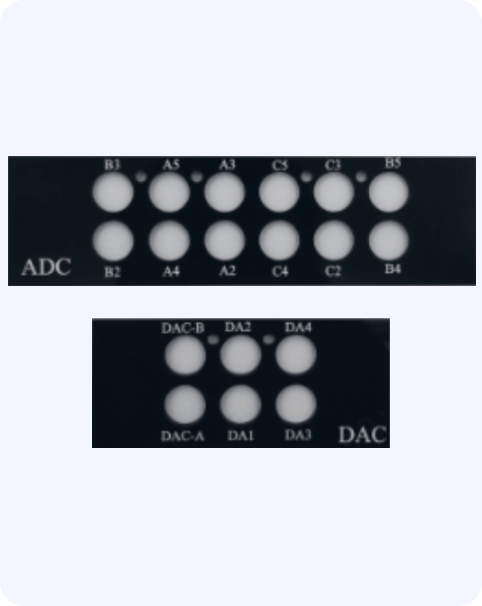

LCSC offers drilling & contour cutting. Laser-based, we don't support counterbores, steps, or chamfers currently.

LCSC offers diverse colors & gradients for the front panels, with no additional cost for variety or quantity.